It may be surprising for some to learn that water is employed as a means of cutting some of the most durable materials used in a wide range of industries today. When compared to other industrial cutting methods available, such as laser cutting and plasma cutting, water jet cutting is capable of cutting a wider array of materials as it does not employ heat.

The benefits of not using heat in industrial cutting are that many materials suffer thermal stress when they are exposed to high temperatures. It is possible for some materials to warp or become deformed when they are cut with heat. In turn, more quantities of material end up being wasted. As those who work with these materials are aware, this can start to become rather costly.

Water jet cutting does not require the use of heat. In the process, mixing water with an abrasive substance, such as garnet or sand, comprises a water solution. Aluminum was once used as the abrasive substance, but the process was messy and the solution could only be used once. It is the abrasive that is responsible for cutting through the thick material.

Once the water is mixed with the abrasive substance, it is shot out of a concentrated area, a small nozzle, with compressed air and at a velocity of up to three times the speed of sound. Some who witness the process may note the unexpectedly high volume of the water jet cutting process. It will also be noted that the process itself is quick and clean, with minimal clean up required afterwards.

Because water jet cutting does not employ the use of heat, it is capable of cutting a wide variety of different materials, such as the following:

-

Plastic

-

Rubber

-

Glass

-

Carpet

-

Stainless Steel

-

Aluminum

-

Brass

-

Stone

-

Marble

-

Granite

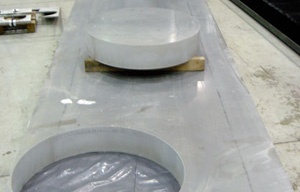

The home renovation industry depends heavily upon water jet cutting as this is the most dependable method of industrial cutting when it comes to cutting stone, marble and granite. These products are not only extremely durable, they are quite costly, meaning that it is important that few mistakes occur in order to remain as cost effective as possible.

Through the use of the flexible water jet stream that can hinge on a multi-axis, water jet cutting is capable of rendering intricate shapes and patterns, as well as elevated, three-dimensional designs. For this reason, professionals in fields such as the home renovation industry, rely heavily on water jet cutting, as it enhances the range of products they can offer.

The construction industry also depends upon water jet cutting to cut rubber and plastic used to develop products such as precisely sized tubes. Using a heat cutting method would melt or deform the material. Water jet cutting allows for high precision cuts for perfectly sized products.

In a world that is becoming increasingly conscious of environmental matters, water jet cutting also offers a green-friendly means of industrial cutting, as there is no hazardous waste to dispose of when the process is complete.

Water jet cutting offers an effective and time efficient means of industrial cutting for Ontario professionals.